is an innovative zinc-aluminium-magnesium

based alloy technology

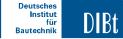

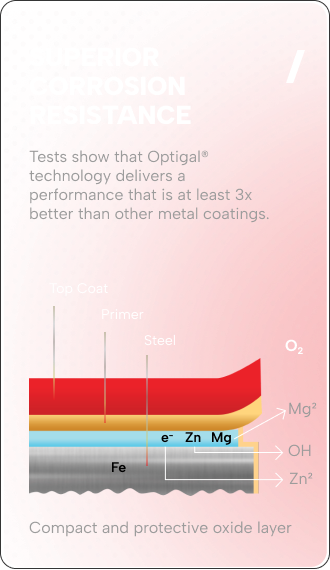

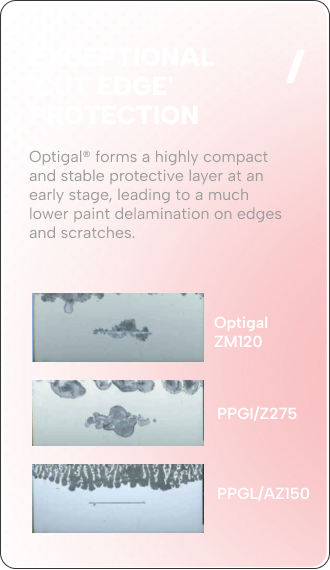

Optigal® steel coating is produced by hot dip galvanization of the steel in a unique bath of zinc-aluminium-magnesium alloy. This creates the ideal substrate for pre-painted steel with magnesium in the alloy coating reducing 'edge creep' while the zinc providing traditional cathodic protection.

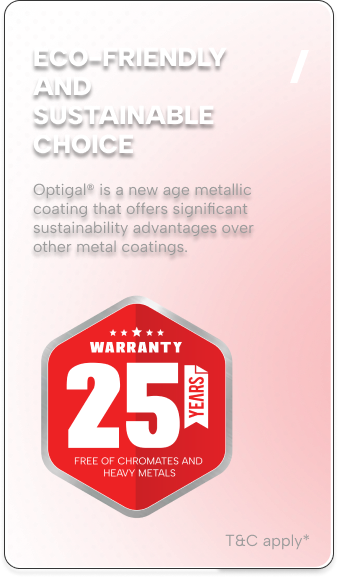

AN ECO-FRIENDLY

AND SUSTAINABLE

CHOICE

T&C apply*

-

/01

This product is eco-friendly because it is free of hexavalent chromium and heavy metals, minimizing its environmental impact and promoting safety and sustainability.

-

/02

Optigal®️ ensures the preservation of natural resources by using less zinc than pure zinc coatings. It limits soil pollution by zinc oxides.

-

/03

Increases lifetime expectancy of building, reduces CO2 emissions by using lighter elements.

INTERNATIONALLY

TESTED AND

CERTIFIED

ADVANTAGES

The unique alloy composition of  with optimal balance between zinc, aluminium and magnesium, provides superior corrosion resistance.

with optimal balance between zinc, aluminium and magnesium, provides superior corrosion resistance.

-

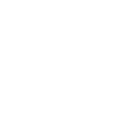

Steel Cladding01

Steel Cladding01 -

Roofing Profiles02

Roofing Profiles02 -

Sandwich Panels03

Sandwich Panels03 -

Roofing Tiles04

Roofing Tiles04 -

Architectural Facade05

Architectural Facade05

| Parameter | Specifications |

| Thickness (mm) | 0.40 - 0.80 mm |

| Thickness Tolerance | 0.40 - 0.60 - +/-0.025 mm 0.60 - 0.80 - +/-0.03 mm Or as per order condition |

| Width Range | 1000 - 1250 mm |

| Width Tolerance | +/-0 mm |

| Mechanical Properties Ref Standard - EN10346:2015 |

S250GD / S280GD / S320GD / S350GD / S550GD |

| ZM Coating | ZM 80 - ZM120 |

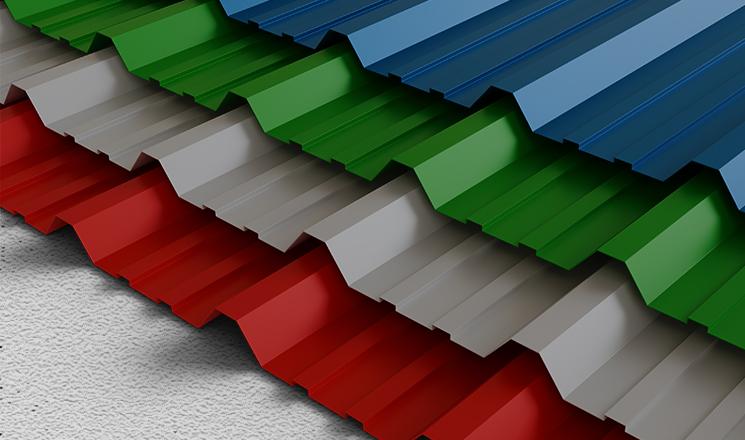

| Paint Type | RMP/SMP/SDP/PVDF |

| Top Coat- DFT (μ) | 5μ Primer + 20μ Top Coat* |

| Bottom Coat- DFT (μ) | 5μ Primer + 5μ Back coat* |

| *Lower/Higher coating can also be supplied on case to case basis | |

| Parameter | Specifications |

| Pencil Hardness | 2H |

| T Bend | 3T - S250GD / S280GD / S350GD 6T - S 550GD |

| MEK | 100 DR min |

| Scratch Resistance | 1.5 Kg |

| Cross Hatch | 1mm X 1mm |

| Reverse Impact | 10 J min S550GD - NA |

| QUV (300 hrs) ASTM G 53-94 | DE - 5max Gloss Retention - 30%min |

| Gloss | 30 - 60 GU or < 30 |

| Delta E | < 1.0 for Light Shade < 1.5 for Dark Shade NA for Metallic and Wrinkle Shades |

| Parameter | Specifications |

| Guard Film | As per order (50µ min) |

| Packing | Standard Metal Packing |

| Coil Wt | 1.50 MT - 10 MT |

| Liner Marking | Sandwich Liner Marking (Ink Jet Printing - Under Back coat) |

| AMNS Monogram | As per order |

| ID Sleeve | 5 mm Card Board Sleeve |

Get to know more

If you would like to discover our product in detail, simply download the brochure

Send Enquiry