Surakshit Sapne. Surakshit Apne.

Galvanised Corrugated Sheets

Coated Steel Galvanised Corrugated Sheets

Galvanised Corrugated Sheets

Galvanised Corrugated Sheets

Galvanised Corrugated SheetsAbout AM/NS Suraksha

A range of Galvanised Corrugated Sheets

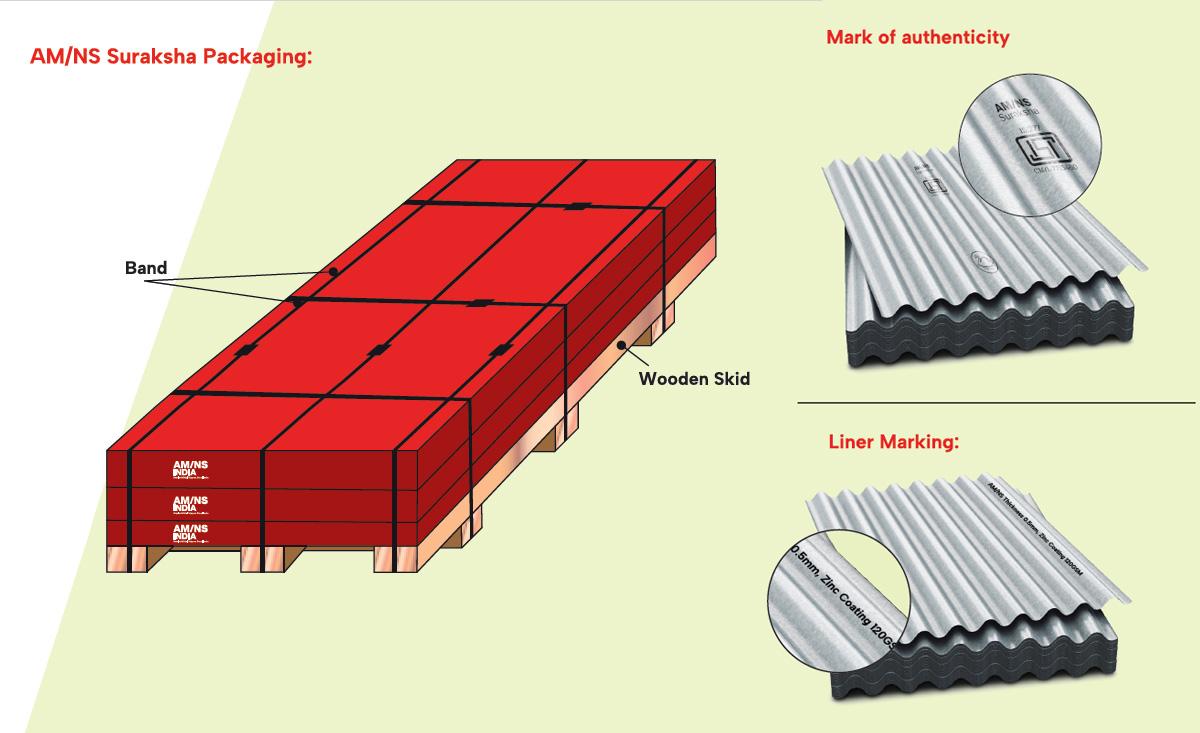

AM/NS Suraksha is known for its superior strength and longer life. Coated with 120 GSM zinc, the sheets have perfect

corrugation and are corrosion resistant. Light weight and High Tensile Strength makes it a preferred choice for all the roofing and cladding applications.

Applications

Superior Strength, Longer Life. Superior Strength, Longer Life. Superior Strength, Longer Life. Superior Strength, Longer Life. Superior Strength, Longer Life.

Specifications

Physical Profile

Tolerance Levels & Others

| Weight Chart for AM/NS Suraksha | |||||||||||

| AM/NS Suraksha Approximate Weight per sheer (For 120 GSM Coating) | |||||||||||

| Input Width | Output Width | GP Thickness | WT IMTR | 6Ft | 7Ft | 8Ft | 9Ft | 10Ft | 12Ft | 14Ft | 16Ft |

| 1830 | 2135 | 2440 | 2745 | 3050 | 3660 | 4270 | 4880 | ||||

| 0.12 | 0.848 | 1.55 | 1.81 | 2.07 | 2.33 | 2.59 | 3.10 | 3.62 | 4.14 | ||

| 0.14 | 9.18 | 1.68 | 1.96 | 2.24 | 2.52 | 2.80 | 3.36 | 3.96 | 4.48 | ||

| 0.16 | 1.067 | 1.95 | 2.28 | 2.60 | 2.93 | 3.25 | 3.91 | 4.56 | 5.21 | ||

| 0.18 | 1.201 | 2.20 | 2.56 | 2.93 | 3.30 | 3.66 | 4.40 | 5.13 | 5.86 | ||

| 0.20 | 1.328 | 2.43 | 2.84 | 3.24 | 3.65 | 4.05 | 4.86 | 5.67 | 6.48 | ||

| 0.22 | 1.413 | 2.59 | 3.02 | 3.45 | 3.88 | 4.31 | 5.17 | 6.03 | 9.90 | ||

| 740 mm | 0.25 | 1.646 | 3.01 | 3.51 | 4.02 | 4.52 | 5.02 | 6.02 | 7.03 | 8.03 | |

| 760 mm | 0.3 | 1.908 | 3.49 | 4.07 | 4.66 | 5.24 | 5.82 | 6.98 | 5.15 | 9.31 | |

| 900 mm | 780 mm | 0.35 | 2.24 | 4.10 | 4.78 | 5.47 | 6.15 | 6.83 | 8.20 | 9.56 | 10.93 |

| 800 mm | 4.0 | 2.572 | 4.71 | 5.49 | 6.28 | 7.06 | 7.84 | 9.41 | 10.98 | 12.55 | |

| 0.45 | 2.897 | 5.30 | 6.19 | 7.07 | 7.95 | 8.82 | 10.60 | 12.37 | 14.14 | ||

| 0.50 | 3 | 5.91 | 6.87 | 7.88 | 8.86 | 9.89 | 11.82 | 13.79 | 15.76 | ||

| 0.55 | 3.589 | 6.57 | 7.66 | 8.76 | 9.85 | 10.95 | 13.14 | 15.33 | 17.51 | ||

| 0.60 | 3.971 | 7.27 | 8.48 | 9.69 | 10.9 | 12.11 | 14.53 | 16.96 | 19.38 | ||

| 0.65 | 4.4 | 8.05 | 9.39 | 10.74 | 12.85 | 13.42 | 16.10 | 18.79 | 21.47 | ||

| 0.70 | 4.698 | 8.60 | 10.03 | 11.46 | 12.9 | 14.33 | 17.19 | 20.06 | 22.93 | ||

| 0.75 | 5.016 | 9.18 | 10.71 | 12.24 | 13.77 | 15.30 | 18.36 | 21.42 | 24.48 | ||

| 0.12 | 0.942 | 1.72 | 2.01 | 2.30 | 2.59 | 2.87 | 3.45 | 21.42 | 6.06 | ||

| 0.14 | 1.02 | 1.87 | 2.18 | 2.49 | 2.8 | 2.87 | 3.73 | 4.02 | 4.98 | ||

| 0.16 | 1.185 | 2.17 | 2.53 | 2.89 | 3.25 | 8.11 | 4.34 | 4.36 | 5.78 | ||

| 8.18 | 1.334 | 2.44 | 2.85 | 3.25 | 3.68 | 3.61 | 4.88 | 5.06 | 6.51 | ||

| 0.20 | 1.475 | 2.70 | 3.15 | 3.6 | 4.05 | 3.614 | 5.4 | 5.7 | 7.20 | ||

| 0.22 | 1.570 | 2.87 | 3.35 | 3.83 | 4.31 | 4.05 | 5.75 | 6.3 | 7.66 | ||

| 0.25 | 1.829 | 3.35 | 3.90 | 4.46 | 5.02 | 4.79 | 6.69 | 7.81 | 8.93 | ||

| 860 mm | 0.30 | 2.119 | 3.88 | 4.52 | 5.17 | 5.82 | 5.58 | 7.76 | 9.05 | 10.34 | |

| 900 | 880 | 0.35 | 2.488 | 4.55 | 5.31 | 6.07 | 6.83 | 6.46 | 9.11 | 10.62 | 12.14 |

| 900 mm | 860 mm | 0.4 | 2.857 | 5.23 | 6.1 | 6.97 | 7.84 | 7.59 | 10.46 | 12.2 | 13.94 |

| 0.45 | 3.218 | 5.89 | 6.87 | 7.85 | 8.83 | 9.81 | 11.78 | 13.74 | 15.7 | ||

| 0.5 | 3.587 | 6.56 | 7.68 | 8.75 | 9.85 | 10.94 | 13.13 | 15.32 | 17.5 | ||

| 0.55 | 3.987 | 7.30 | 8.51 | 9.73 | 10.94 | 12.16 | 14.59 | 17.02 | 19.46 | ||

| 0.6 | 4.411 | 8.07 | 9.42 | 10.76 | 12.11 | 13.45 | 16.14 | 18.83 | 21.53 | ||

| 0.65 | 4.89 | 8.95 | 10.44 | 11.93 | 13.42 | 14.91 | 17.9 | 20.88 | 23.86 | ||

| 0.70 | 5.22 | 9.55 | 11.14 | 12.74 | 14.33 | 15.92 | 19.11 | 22.29 | 25.47 | ||

| 0.75 | 5.573 | 10.2 | 11.9 | 13.60 | 15.30 | 17 | 20.4 | 23.8 | 27.2 | ||

| 0.25 | 2.414 | 4.42 | 5.15 | 5.89 | 6.63 | 7.36 | 8.84 | 10.31 | 11.78 | ||

| 0.30 | 2.797 | 5.12 | 5.97 | 6.82 | 7.68 | 8.53 | 10.24 | 11.94 | 13.65 | ||

| 0.35 | 1284 | 6.01 | 7.01 | 8.01 | 9.01 | 10.02 | 12.02 | 14.02 | 16.03 | ||

| 1320 mm | 1220 mm | 0.40 | 3.77 | 6.90 | 8.05 | 9.20 | 10.35 | 11.5 | 13.80 | 16.1 | 18.40 |

| 0.45 | 4.248 | 7.77 | 9.07 | 10.37 | 11.66 | 12.96 | 15.55 | 18.14 | 20.73 | ||

| 0.50 | 4.735 | 8.61 | 10.11 | 155 | 13.00 | 14.44 | 17.33 | 20.22 | 23.11 | ||

| 0.55 | 5.263 | 9.63 | 11.24 | 12.84 | 14.45 | 16.05 | 19.26 | 22.47 | 25.68 | ||

| 0.60 | 5.647 | 10.33 | 12.06 | 13.78 | 15.50 | 17.22 | 20.67 | 24.11 | 27.56 | ||

| Physical Profile of AM/NS Suraksha | ||||

| Input Width (mm) | Output Width of GC Sheets After Corrugation (mm) | Depth of Corrugation (mm) | Pitch of Corrugation (mm) | No. of Corrugations |

| 900 | 740 | 20/21(+/-2.5) | 70(+/-5) | 10+1/2+1/2 |

| 900 | 760 | 19.5/20 (+/-2.5) | 71(+/-5) | 10+1/2+1/2 |

| 900 | 780 | 19/19.5(+/-2.5) | 72(*/-5) | 10+1/2+1/2 |

| 900 | 800 | 17.6/18 ( 47-2.5) | 76.2 (+/-5) | 10+1/2+1/2 |

| 1000 | 860 | 16/l7(+/-2.5) | 76.2(+/-5) | 12+1/2+1/2 |

| 1000 | 880 | 15/l6(+/-2.5) | 76.2(+/-5) | 12+1/2+1/2 |

| 1000 | 900/910 | 15/16(+/-2.5) | 76.2(+/-5) | 12+1/2+1/2 |

| 1320 | 1220 | 14/15(+/-2.5) | 72(+/-5) | 15+1/2+1/2 |

| Tolerance Levels and Other Specifications - AM/NS Suraksha tolerance | ||

| Levels confirm to BIS specifications owing to superior process control. | ||

| Parameter | UOM | Tolerance |

| Bundle Weight (70/72 running feet of sheets) | % | +/- 0.50 |

| Thickness Tolerances | mm | ± 0.05 |

| Length Tolerance | mm | +15.0.-0.0 |

| Width Tolerances | mm | ± 25.0 [IS277 -2018 (Clause 15.2.1) table no 9] |

| Depth of Corrugation | mm | ± 2.5 (IS277 -2018 (Clause 15.2.1) table no 9) |

| Pitch of Corrugation | mm | ± 5.0 [IS277 -2018 (Clause 15.2.1) table no 9] |

| Yield Strength | MPa | 550 min |

| Zinc Coating | GSM | Min 120 (as per BIS clause 7.1 & 10.1) |

| Spangles | Finish | Regular and Bright |

Get to know more

If you would like to discover our product in detail, simply download the brochure

Send Enquiry

Please feel free to reach out to us and we'll get back to you promptly.