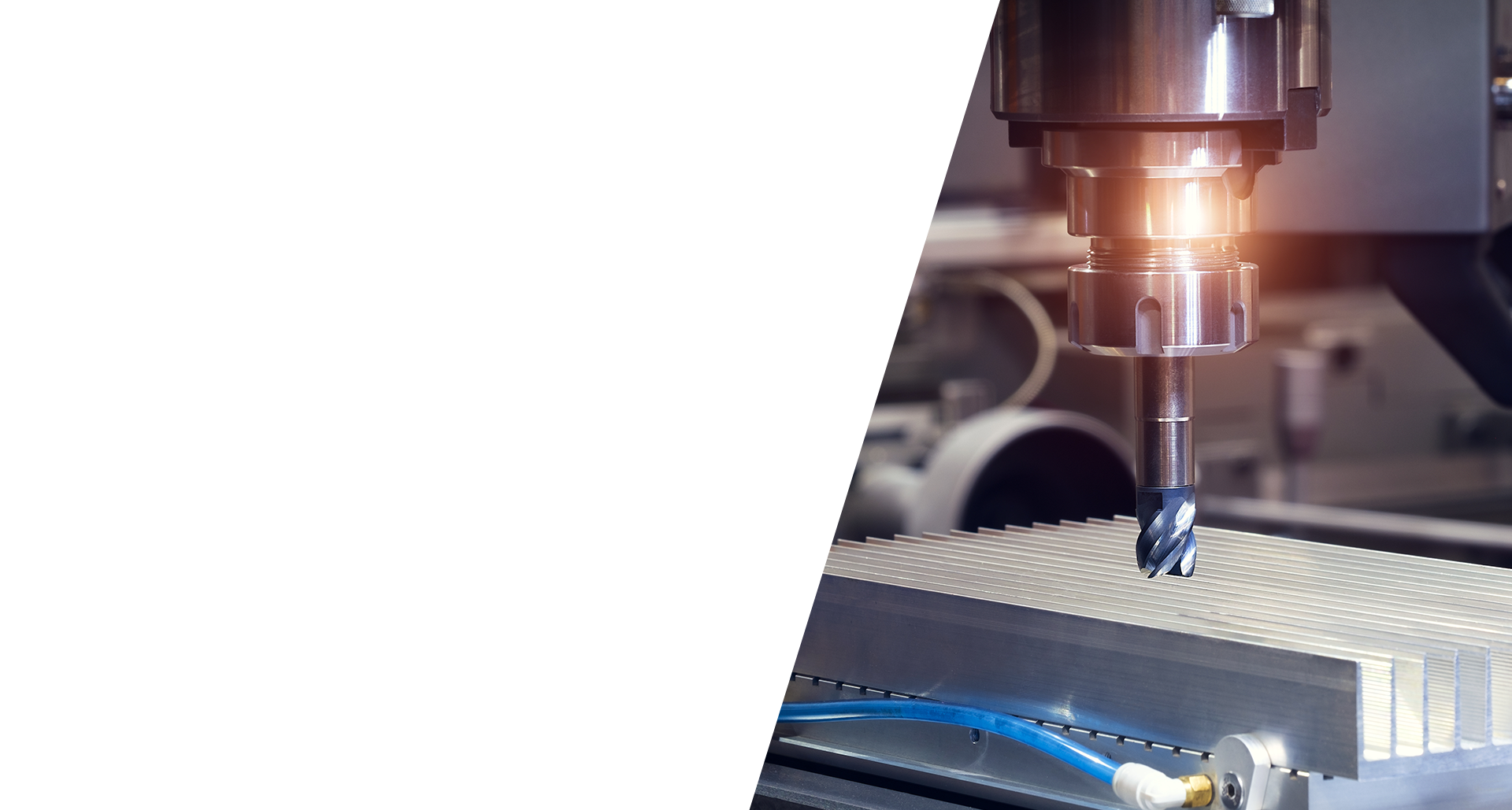

High Quality Cold Rolled Coils & Sheets

Manufacturing

Our flagship manufacturing complex at Hazira commands a leading position in the cold rolling

segment, with a

capacity of 2 MTPA, through a 6 Hi Hitachi mill and a tandem mill. Coils are

rolled from between 0.40 mm and 3.2 mm

in width and range from 200 mm to 1,625 mm in length.

Our Cold Rolled Close Annealed (CRCA) products

demonstrate high strength, ductility and

uniform mechanical properties with close dimensional control and superior

surface finish.

Our CRCA products are manufactured in deep drawing, extra deep drawing, interstitial free steels

and high strength

grades, all conforming to various national and international standards. We

employ an automatic gauge control (AGC)

system to guarantee dimensional accuracy.

The cold rolled steel mill at Hazira ensures we consistently deliver high-quality products for

critical applications in

sectors such as automotive, semi- processed electrical steel,

packaging, medium carbon and high carbon, boron steel

and general engineering.

Our cold rolled mills offer the following features

Manufacturing Process

Technology Providers

| Equipment | Supplier |

| 6 Hi Reversible Rolling Mill | HITACHI, Japan |

| Continuous Tandem Cold Rolling Mill 4 Hi 5 Stands |

VAI CLECIM, France |

| Batch Annealing Furnace |

EBNER - Austria LOI - Belgium SECO WARWICK - Germany Alied - India |

| Electrolytic Cleaning Line | VAI CLECIM, France |

| 4 Hi Cold Skin Pass Mill | VAI CLECIM, France |

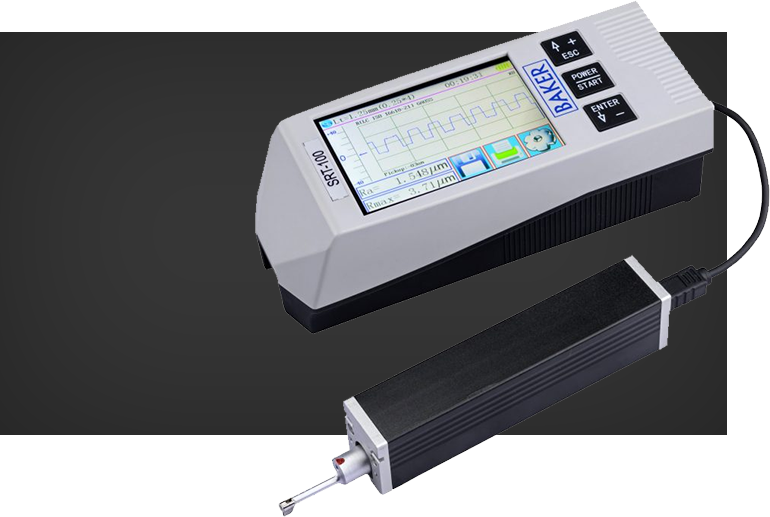

Testing Facilities

Testimonials

FAQs

Steel is an alloy of Iron and Carbon. Steel is divided as Low Carbon (Mild Steel) , Medium Carbon and High Carbon Steel based on carbon content & killed, semi killed and rimming Steel based on deoxidation process. Application of steel involves in various automobile, white goods and structural applications.

Pig iron, steel scrap, ferro alloys, lime, Do-lime etc.

CRCA is Cold Rolled Close Annealed material. Applications of CRCA includes mostly in automotive, white goods applications.

Hot Rolled coils are firstly pickled in hydrochloric acid then cold rolled (below Recrystallization temperature) in successive passes in a cold rolling mill then the cold rolled coil is electrolytically cleaned and then annealed in batch type furnaces in hydrogen atmosphere and Skin passed with application of rust preventive oil to make CRCA in different grades and textures (Bright & Matte)

Cold rolling is the mechanical working of the Steel below its Recrystallisation Temperature to achieve close thickness tolerances, better surface finish. Various grades rolled in flat form are D, DD, EDD, IF grade, High Tensile strength.

Pickling is the process of Acid cleaning of the sheet which removes iron oxide scales from the surface of the strip. These Oxide layers are to be essentially removed for smooth cold rolling operation & better surface quality. Hydrochloric Acid is generally used in Pickling process.

Auto gauge control (AGC), Auto Shape control, X-Ray gauge, Universal crown & IMR Shifting to have better thickness tolerances, good shape in comparison to other Rolling mills.

Electrolytic cleaning process can remove micro fines of Iron & Dirt and other unwanted foreign particles from cold rolled steel strip surface. This cannot be obtained from conventional cleaning processes.

Silicated Alkali with other additives like surfactants etc. is used to achieve required level of cleanliness.