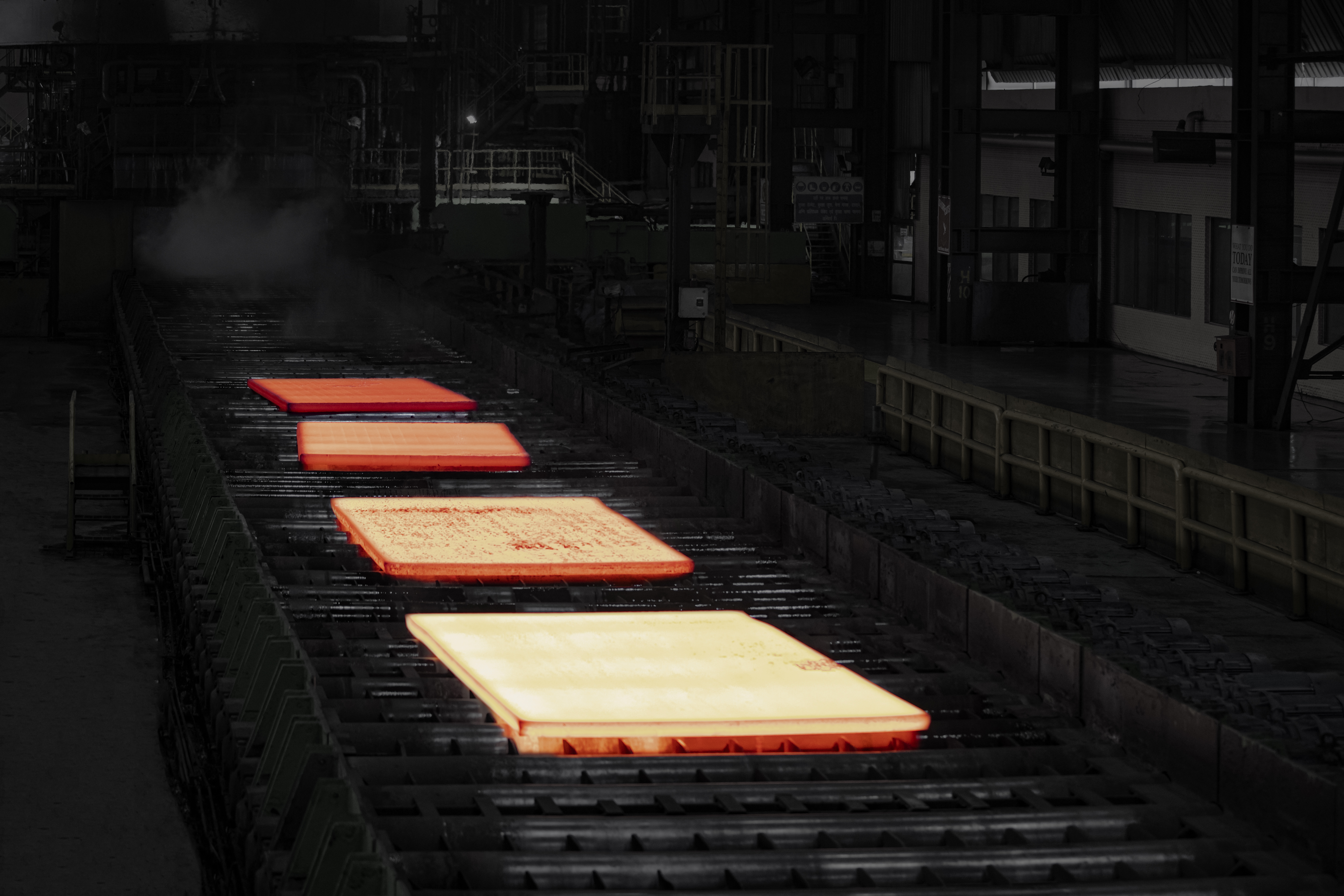

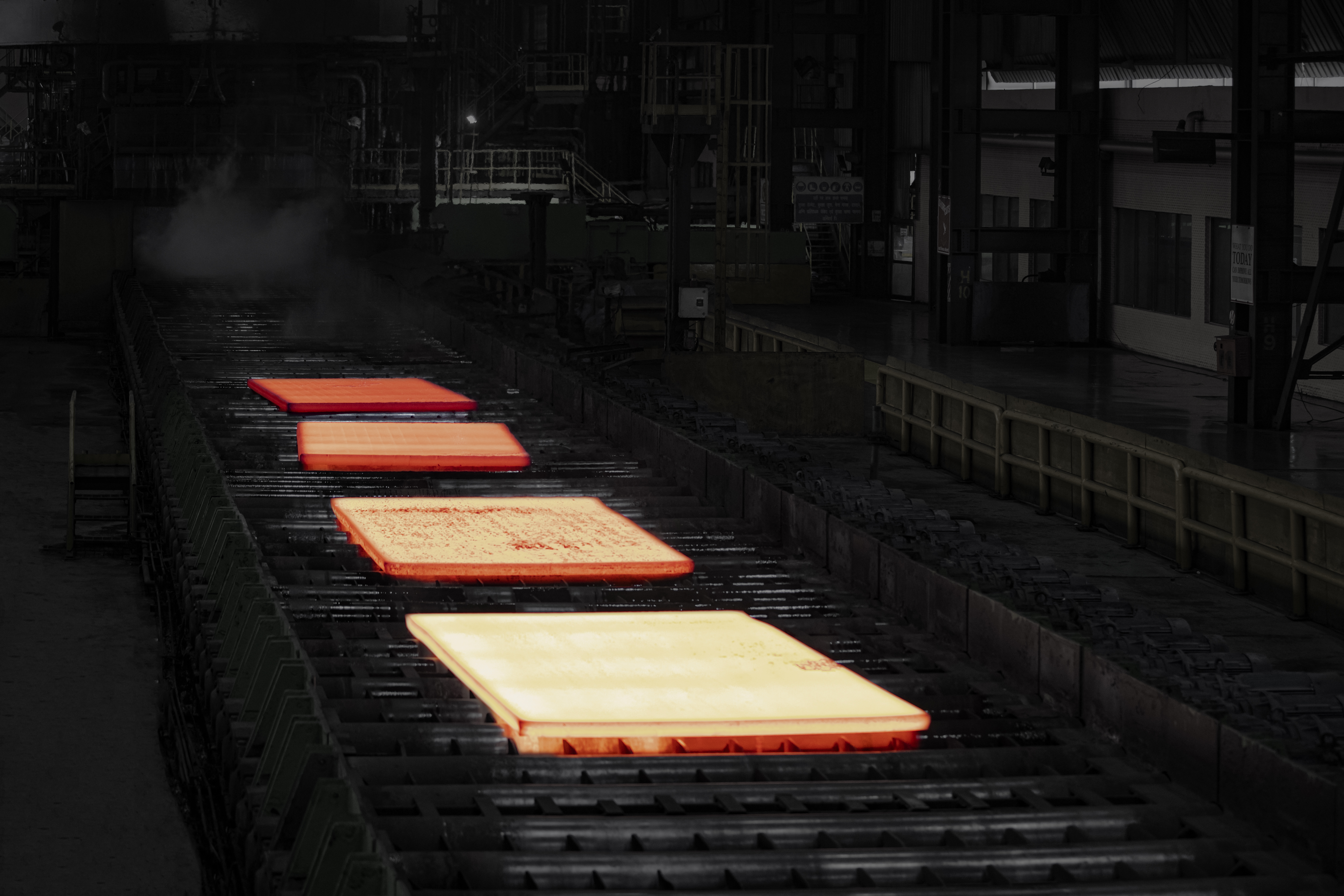

Steel Plate Processing: Cutting, Bending, and Welding

As an industry leader in the manufacturing of heavy plates, customize heavy plates, and other steel products, here at AM/NS India, we understand the critical role that steel plate processing plays in various industries, from construction to manufacturing. In this blog post, we will explore the processes of steel plate processing, focusing on cutting, bending, and welding techniques.

Steel Plate Processing: An Overview

Cutting Heavy Plates

One of the fundamental processes required for the manufacture and customize heavy plates in steel plate processing is cutting. Heavy plates come in various sizes and thicknesses, and cutting them accurately to meet specific project requirements is essential. At AM/NS India, as a manufacturer of steel plates, we utilize advanced cutting technologies such as plasma cutting, laser cutting, and oxy-fuel cutting to achieve precision and efficiency in our operations.

Plasma cutting is a process that is particularly effective for cutting through thick steel plates, offering high speeds and excellent cut quality. On the other hand, laser cutting provides unmatched precision, making it ideal for intricate shapes and designs. Oxy-fuel cutting, although slower compared to plasma and laser cutting, is highly versatile and cost-effective, making it suitable for a wide range of applications.

As a manufacturer of steel, with our state-of-the-art equipment and skilled workforce, we ensure that every steel plate is cut to perfection, meeting the exact specifications of our clients.

Bending Heavy Plates

Once the heavy steel plates are cut to size, they often require bending to achieve the desired shapes or forms, and these are essential steps when we are looking to customize steel plates. Bending is a critical process in steel fabrication, enabling the creation of structural components, machine parts, and various other products.

At AM/NS India, we utilize hydraulic press brakes and plate rolling machines to bend heavy plates with precision and accuracy. Hydraulic press brakes offer immense power and control, allowing us to bend thick steel plates effortlessly. Plate rolling machines, on the other hand, are ideal for curving and shaping large steel plates, enabling us to produce cylinders, cones, and other curved components.

Our skilled operators and engineers ensure that every bend meets the strictest quality standards, guaranteeing the structural integrity and dimensional accuracy of the final product.

Welding Heavy Plates

Welding is the process of joining two or more metal pieces together, and it plays a crucial role in steel plate processing. Whether it's constructing bridges, buildings, or machinery, welding is essential for creating robust and durable structures.

At AM/NS India, we employ various welding techniques such as arc welding, MIG welding, and TIG welding to join heavy plates effectively. Each welding method offers unique advantages, depending on the specific requirements of the project. Arc welding, for instance, is known for its versatility and suitability for thick steel plates, while MIG welding excels in high-speed production environments. TIG welding, with its precision and cleanliness, is often used for critical applications where aesthetics are paramount.

Our certified welders undergo rigorous training and adhere to strict quality control measures to ensure that every weld meets the highest industry standards for strength, integrity, and appearance.

Conclusion:

Steel plate and heavy steel processing is a complex yet essential aspect of modern manufacturing and construction. Whether it's cutting, bending, or welding heavy plates, precision and quality are paramount. Here at AM/NS India, we pride ourselves on being a leading manufacturer of steel, specializing in the production of heavy plates and providing top-notch processing services to our clients.

If you're looking for a reliable partner for your steel plate processing needs, look no further than AM/NS India. Contact us today to learn more about our capabilities and how we can assist you in your next project.

Explore our latest Post