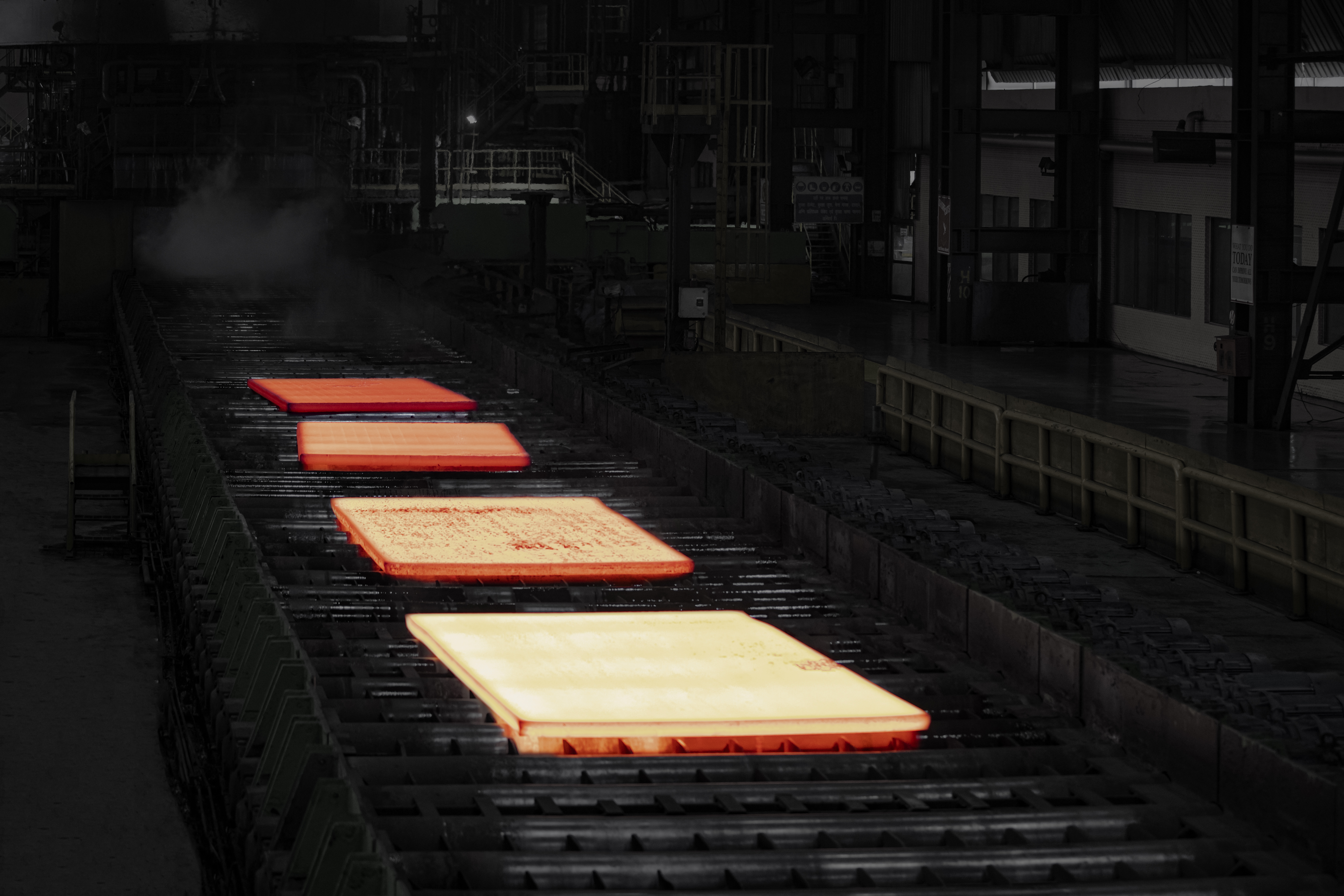

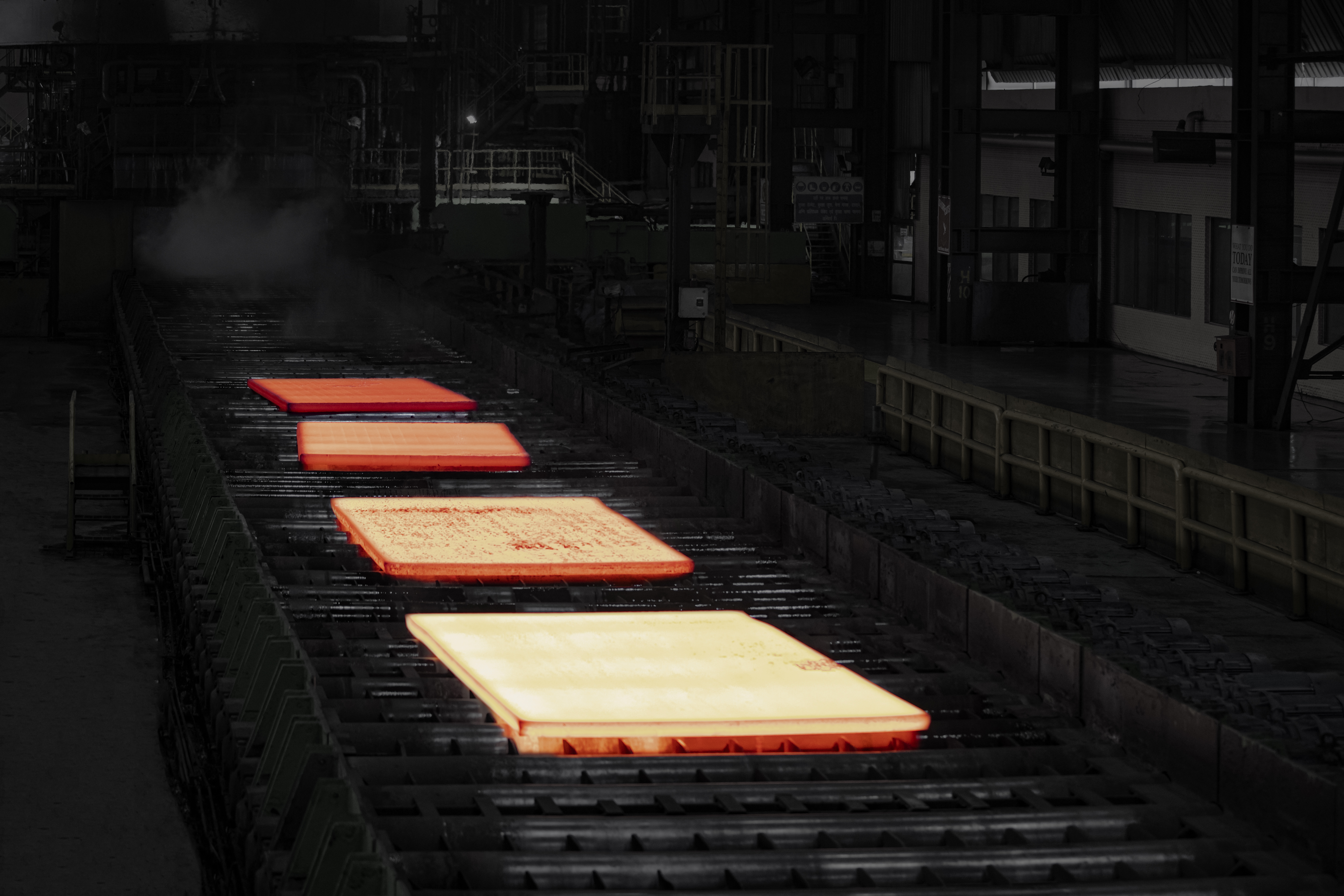

Heavy Plate Coatings and Treatments: Ensuring Durability and Corrosion Resistance

In the field of industrial applications, the significance of heavy plates, particularly steel plates, cannot be overstated. These components are foundational in numerous sectors, including construction, shipbuilding, and heavy machinery manufacturing. However, the longevity and reliability of these plates hinge on effective coatings and treatments that enhance their durability and corrosion resistance.

The Imperative for Coatings and Treatments

Steel plates, by their very nature, are prone to corrosion when exposed to harsh environmental conditions. Corrosion not only compromises the structural integrity of the steel but also leads to substantial economic losses. According to a study by NACE International, the global cost of corrosion is estimated to be $2.5 trillion annually, which is approximately 3.4% of the global GDP. This staggering figure underscores the necessity for robust protective measures.

Types of Coatings for Heavy Plates

Galvanisation:

Galvanisation involves coating steel plates with a layer of zinc. This process not only provides a physical barrier against corrosive elements but also offers sacrificial protection. When the zinc layer is damaged, it continues to protect the steel by corroding preferentially. Hot-dip galvanising is particularly effective, providing a thick, durable coating.

Epoxy Coatings:

Epoxy coatings are widely used due to their excellent adhesion properties and resistance to chemicals. These coatings form a hard, protective layer that shields the steel from moisture and corrosive substances. Epoxy-coated heavy plates are particularly prevalent in the marine and oil and gas industries, where exposure to harsh chemicals and saltwater is common.

Polyurethane Coatings:

Polyurethane coatings offer flexibility and strong resistance to abrasion and impact. These coatings are ideal for applications where heavy plates are subject to mechanical stress. They also provide good UV resistance, making them suitable for outdoor applications where exposure to sunlight can degrade other types of coatings.

Ceramic Coatings:

Ceramic coatings are employed in scenarios where extreme heat resistance is required. These coatings can withstand temperatures exceeding 1,000°C and provide excellent corrosion resistance in acidic and alkaline environments. Heavy plates treated with ceramic coatings are often used in high-temperature industrial processes and power plants.

Surface Treatments Enhancing Durability

In addition to coatings, various surface treatments are employed to enhance the performance of heavy plates. These treatments modify the surface properties of the steel, improving hardness, wear resistance, and overall durability.

Shot Peening:

Shot peening is a mechanical process that involves bombarding the surface of steel plates with small spherical media. This treatment induces compressive residual stresses on the surface, significantly enhancing fatigue strength and resistance to stress corrosion cracking.

Laser Cladding:

Laser cladding is a precision technique where a laser beam melts a coating material onto the surface of a steel plate. This process creates a metallurgical bond that is highly resistant to wear and corrosion. Laser cladding is particularly advantageous for extending the service life of components exposed to extreme operational conditions.

Nitriding:

Nitriding is a heat treatment process that diffuses nitrogen into the surface of the steel, forming a hard, wear-resistant layer. This treatment is especially beneficial for heavy plates used in high-stress environments, such as in mining and earthmoving equipment.

Selecting the Right Manufacturer

Choosing a reputable manufacturer of steel plates is crucial to ensure the quality and performance of heavy plates. AM/NS India adheres to stringent quality control processes and utilises advanced technologies in coating and treatment applications that can significantly enhance the durability and corrosion resistance of steel plates.

Conclusion

The application of advanced coatings and treatments is essential for maximising the durability and corrosion resistance of heavy plates. The selection of appropriate coatings and surface treatments should be based on the specific environmental conditions and operational demands. By partnering with AM/NS India for steel plates, industry stakeholders can ensure the longevity and performance of their heavy plate components, ultimately leading to reduced maintenance costs and improved safety.

Implementing these protective measures is not just a matter of economic efficiency but also a critical aspect of maintaining structural integrity in critical applications. As a manufacturer of steel, the development and adoption of innovative coating and treatment technologies will remain pivotal in safeguarding the future of heavy plate usage.

Explore our latest Post