Exploring the Steps of Heavy Steel Plates Manufacturing

The production of heavy steel plates is a complex and meticulously controlled process, ensuring that the final product meets the demanding specifications required for various industrial applications. Whether used in shipbuilding, construction, or heavy machinery, the quality of steel plates is paramount. Understanding the manufacturing process offers insight into the rigorous standards upheld by a reputable steel plates manufacturer.

Raw Material Selection and Preparation

The journey of a heavy steel plate begins with the selection of raw materials. Iron ore, coal, and limestone are the primary ingredients used in steelmaking. These raw materials are carefully chosen for their quality and suitability for the specific type of steel being produced. A heavy steel plates company often sources these materials from trusted suppliers to ensure consistency.

Once the raw materials are selected, they undergo a series of processes to prepare them for steelmaking. Iron ore is smelted in a blast furnace to produce molten iron, which is then combined with scrap steel to balance the composition. This process forms the foundation of steel manufacturing, setting the stage for the production of high-quality heavy steel plates.

Steelmaking: Converting Raw Materials into Steel

Steelmaking involves the conversion of molten iron into steel through the Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) methods. In the BOF method, oxygen is blown into the molten iron to reduce carbon content and remove impurities. This process is fast and efficient, capable of producing large quantities of steel. The EAF method, on the other hand, uses electricity to melt scrap steel, offering flexibility in production and the ability to produce specialized steel grades.

During steelmaking, the composition is carefully controlled to ensure that the steel meets the desired chemical specifications. The steel is then cast into slabs, which are the precursor to steel plates. The slabs are cooled and stored before moving on to the next phase.

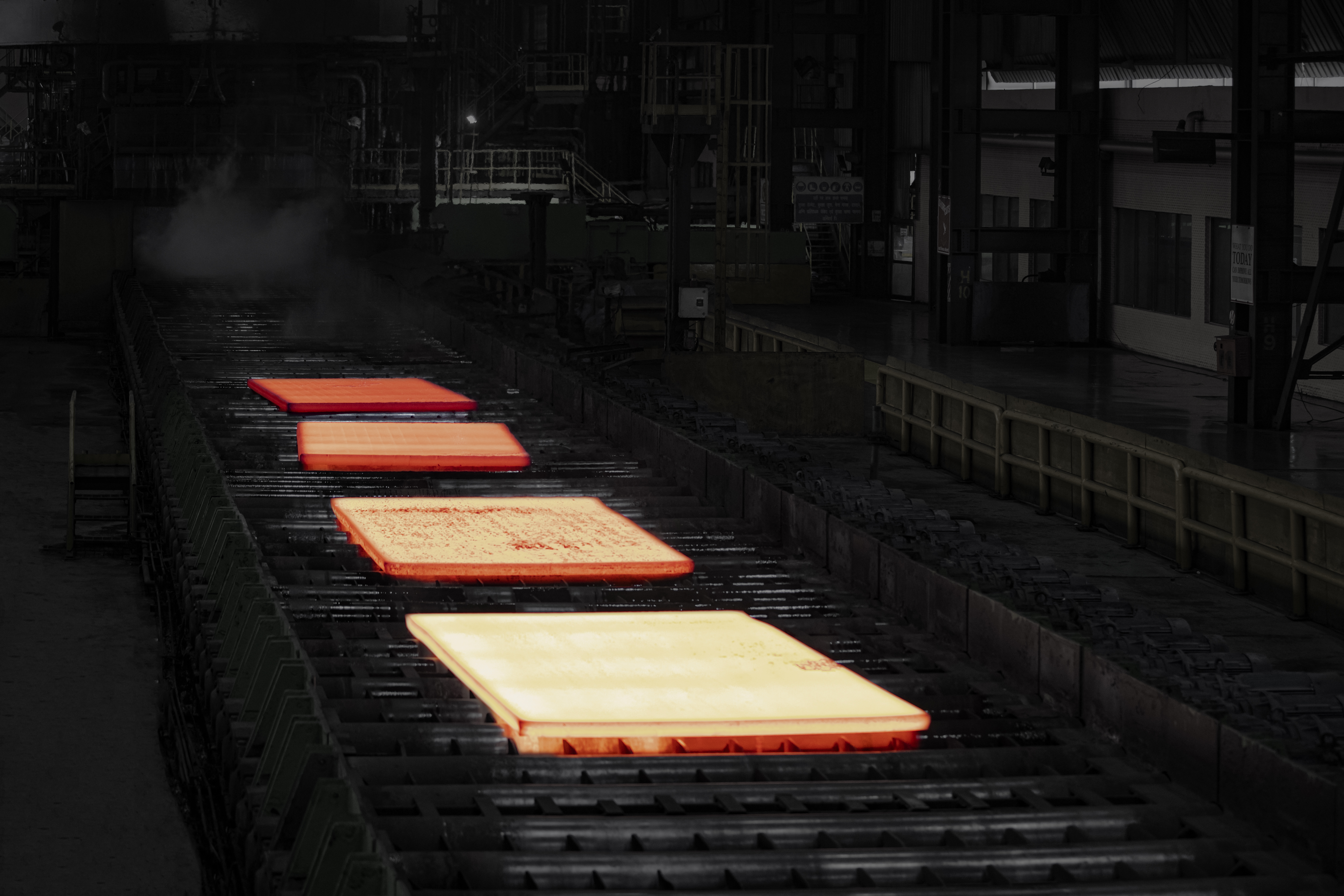

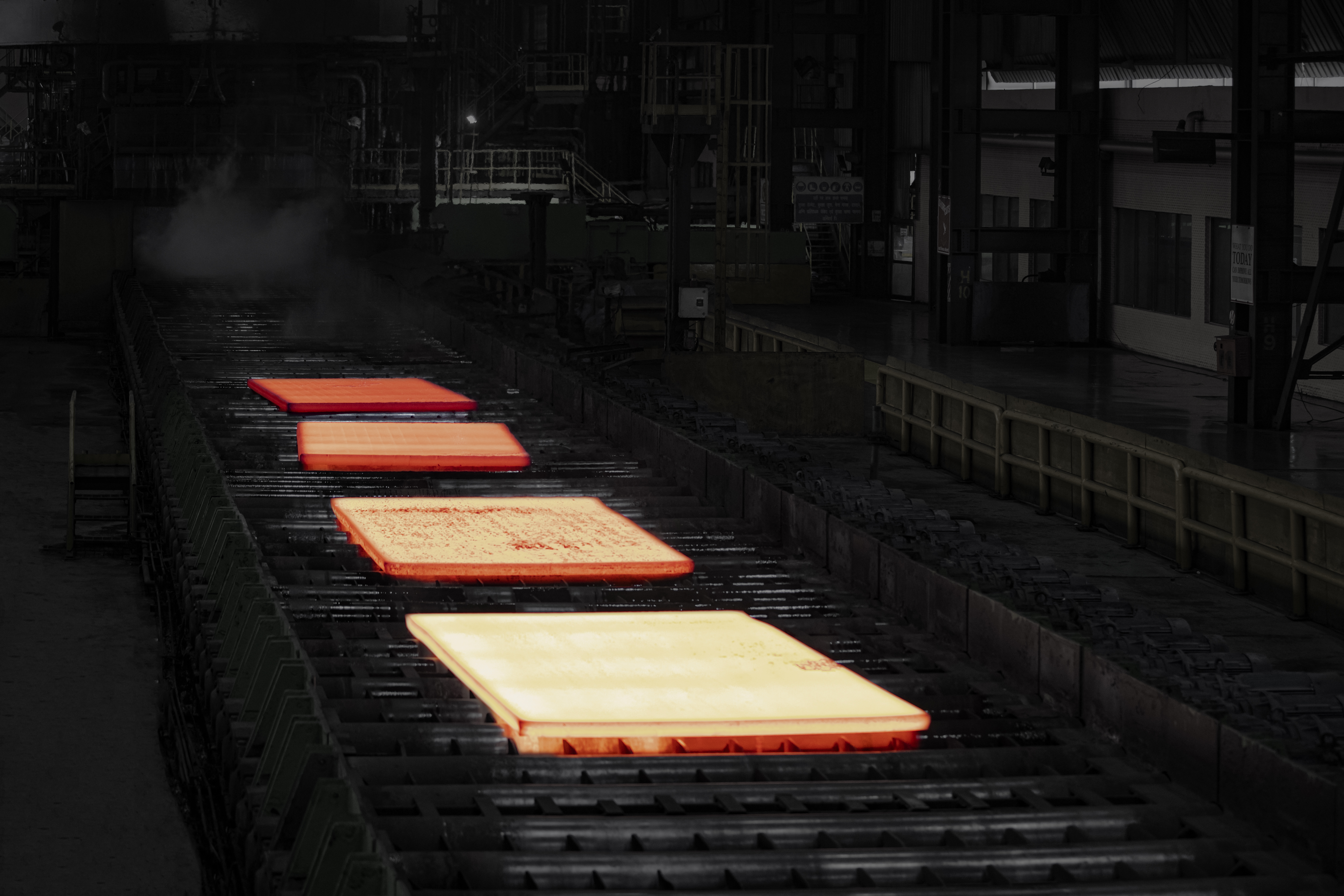

Rolling: Transforming Slabs into Plates

The slabs are reheated in a furnace to temperatures exceeding 1,100°C before being fed into rolling mills. Rolling is a critical step in the manufacturing process, where the slabs are passed through a series of rollers to reduce thickness and achieve the desired plate dimensions.

Hot rolling ensures that the steel plates have uniform thickness and surface quality. The process also aligns the internal structure of the steel, enhancing its mechanical properties such as strength and toughness. A manufacturer of steel plates often invests in state-of-the-art rolling mills to produce plates with precision and consistency.

Heat Treatment: Enhancing Mechanical Properties

After rolling, the steel plates may undergo heat treatment to further refine their mechanical properties. Heat treatment processes, such as annealing, quenching, and tempering, alter the microstructure of the steel to achieve specific hardness, strength, and toughness levels. This step is essential for applications where the steel plates will be subjected to extreme conditions.

Heat treatment is meticulously controlled to ensure that the plates meet the required standards for their intended use. A heavy steel plates company may offer various heat treatment options depending on customer requirements.

Surface Treatment and Finishing

Surface treatment is the next crucial step, where the plates are cleaned, coated, or painted to enhance their durability and resistance to corrosion. Surface treatments may include processes like shot blasting, pickling, or applying protective coatings.

The finishing process also involves trimming the edges of the plates, inspecting for defects, and ensuring that the plates meet the dimensional and surface quality standards specified by the customer. This step ensures that the final product is not only functional but also aesthetically pleasing.

Quality Control: Ensuring Compliance with Standards

Quality control is an integral part of the heavy steel plate manufacturing process. Throughout each stage, from raw material selection to final finishing, the plates undergo rigorous testing to ensure compliance with industry standards. Tests may include ultrasonic testing, tensile strength testing, and impact resistance testing.

A reputable manufacturer of steel plates implements stringent quality control measures to guarantee that the final product meets or exceeds the expectations of its customers. By adhering to these standards, the manufacturer ensures that the plates are suitable for critical applications.

Packaging and Distribution

Once the heavy steel plates have passed quality control, they are packaged for distribution. Packaging is designed to protect the plates during transportation, ensuring they arrive at their destination in pristine condition. The heavy steel plates company then coordinates logistics to deliver the plates to customers across various industries.

Conclusion

The manufacturing of heavy steel plates is a comprehensive process that demands precision, expertise, and a commitment to quality. By understanding the steps involved, industry professionals can appreciate the complexity and skill required to produce steel plates that meet the highest standards. For any project requiring heavy steel plates, partnering with a reliable steel plates manufacturer is crucial to ensuring success.

Explore our latest Post